MIL-S-20706A

position and in the carrying position when not in use and a spring

actuating mechanism when specified (see 3.9.3). When the shank is

in the working position, the housing shall hold the shank vertical

(90 degrees to the ground line in two planes). The housings shall

be constructed so that when the shank is in the carrying position

the bottoom of the tooth shall have a ground clearance of not less

than 1-1/2 inches. The housing shall not extend rearward more than

3 inches from the vertical plane of the working face of the shank.

All bolt holes shall be spaced to fit the mounting brackets within

plus or minus l/32 inch and shall be of the diameter specified for

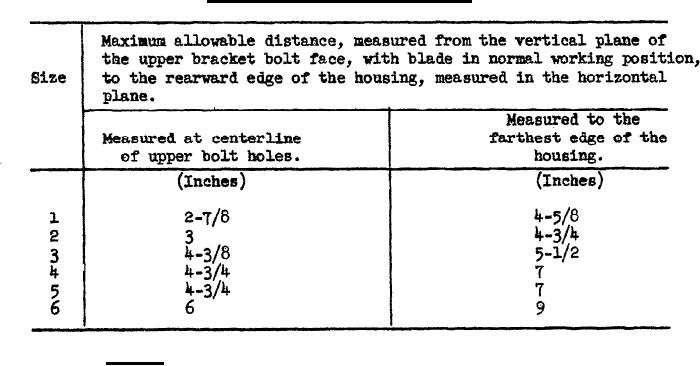

the size of tractor specified. The overall horizontal dimensions

of the housing measured from the vertical plane of the upper mold-

board bracket shall not exceed the amount specified in table IV.

Table IV.

Housing Dimensions

3.9.1 Shank. The shank shall swing from the housing assembly and be

of sufficient length for the tooth to penetrate below the cutting edge

of the dozer not less than the amount specified in table I. Individual

shanks shall be of sufficient strength to withstand the maximum pull

of the tractor without distortion or failure. The entire shank shall

be located rearward of any moldboard surfaces. The horizontal distance

from the cutting edge of the tooth to the vertical working surface of

the shank shall be not less than 7 inches. The shank in any position

of adjustment shall not interfere with any part of the tractor. The

lower tip of the shank shall accept and retain under maximum load a

replaceable teeth conforming to MIL-T-20705. The section of the shank

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business